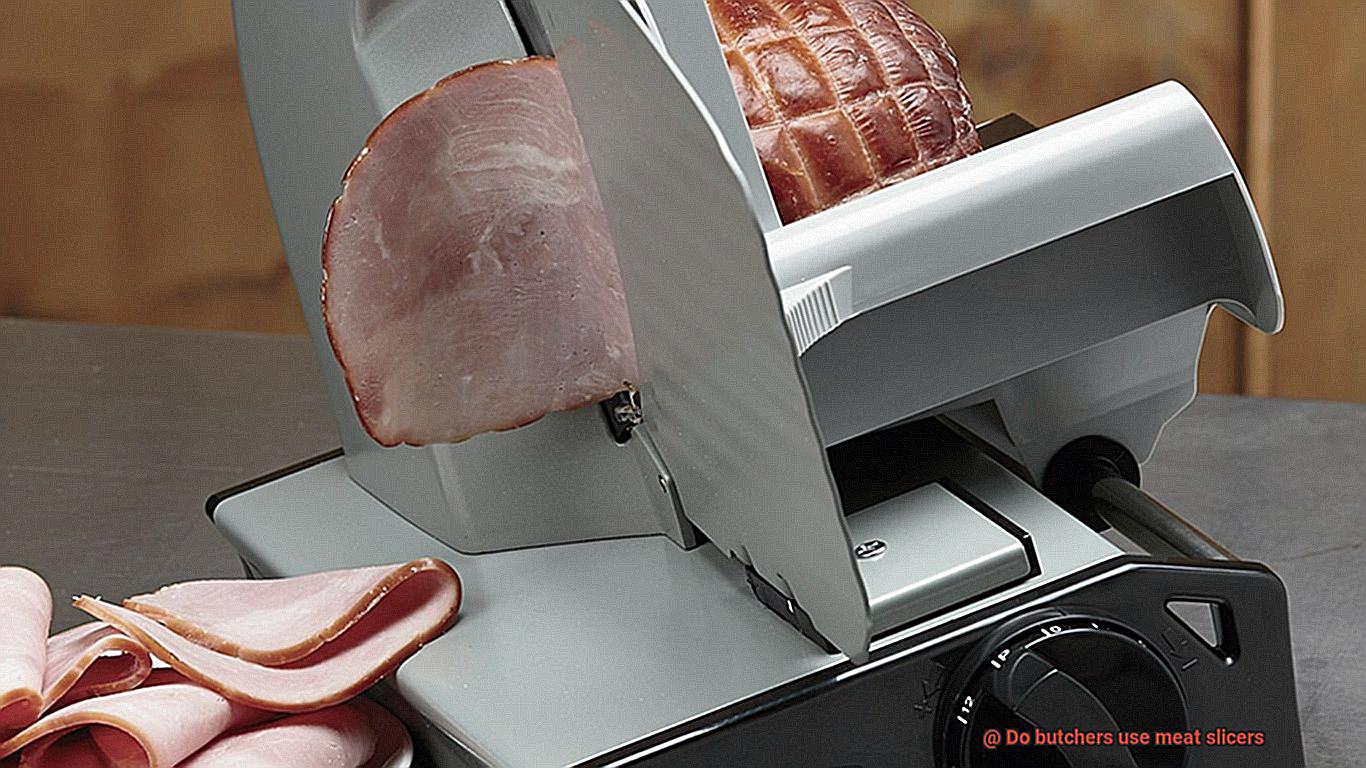

Attention meat lovers. Have you ever marveled at the precise cuts of your favorite meats and wondered how they’re achieved? The answer is simple yet sophisticated: meat slicers. But, do butchers really use them? Yes, they do, and have been for centuries.

Meat slicers are a must-have in any modern butcher shop. They’re lightning-fast, efficient, and produce consistent thicknesses with each slice – an indispensable tool for any professional butcher. But meat slicing wasn’t always this high-tech.

In the olden days, before the invention of meat slicers, butchers would painstakingly cut each slice by hand using a large sharp knife. This process was incredibly time-consuming and often resulted in uneven cuts of meat.

As demand grew for sliced meats, innovators began developing machines to make the process more efficient. The first meat slicer was invented in the late 1800s and since then butchers have been using them to slice everything from deli meats to roasts.

In this blog post, we’ll explore the benefits of using a meat slicer as well as how butchers use them to create perfect slices every time. We’ll also delve into the different types of meat slicers available and how to choose the right one for your needs. So next time you sink your teeth into a perfectly sliced piece of meat, you’ll know exactly how it was achieved.

Contents

The Different Types of Meat Slicers

Meat slicers are vital tools for butchers and other professionals who need to slice meat quickly, efficiently, and precisely. There are several types of meat slicers available on the market, each designed with specific features to meet different needs. Here are five sub-sections that explain the different types of meat slicers commonly used by butchers:

Gravity feed meat slicers

These slicers are the most common type used by butchers. They have a tilted carriage that holds the meat, and the meat slides down towards the blade due to gravity. The blade then slices through the meat evenly, and the slices fall onto a tray. Gravity feed slicers are easy to use, and they are ideal for slicing small to medium-sized cuts of meat. They are also more affordable than other models, making them a popular choice for small businesses.

Automatic meat slicers

These advanced machines are powered by electricity and can be programmed to cut meat at specific thicknesses and speeds. They are ideal for large-scale production and commonly used in processing plants. Automatic slicers are faster and more efficient than manual models but tend to be more expensive. They are also equipped with safety features, such as automatic shut-off switches, to prevent accidents.

Manual meat slicers

These slicers require the butcher to operate the machine by hand. They are ideal for small-scale operations and much cheaper than automatic or gravity feed models. Manual slicers allow for more precise cuts and are great for slicing small quantities of meat or making specific cuts. They also require less maintenance than automatic slicers and can last longer if properly cared for.

Commercial meat slicers

These heavy-duty machines are designed for use in commercial kitchens or processing plants. They can handle large volumes of meat and are built to last longer than other types of slicers. Commercial slicers can be either automatic or manual and are capable of slicing through tough cuts of meat quickly and efficiently. They are also equipped with safety features, such as blade guards, to prevent injuries.

Home use meat slicers

These slicers are smaller than commercial-grade models and designed for home use. They can be used to slice meats, cheeses, and vegetables and are easy to store when not in use. Home use slicers come in both manual and automatic models, making them a great option for home cooks who want to prepare their own deli meats at home. They are also more affordable than commercial slicers, making them accessible to a wider range of consumers.

In conclusion, choosing the right type of meat slicer is crucial for butchers and other professionals who work with meat. The type of slicer you choose will depend on your specific needs and budget. Understanding the differences between these models can help inform your purchasing decision and ensure you get a slicer that meets your requirements.

Benefits of Using a Meat Slicer for Butchers

As a butcher, you understand the importance of precision and speed when it comes to delivering quality cuts of meat to your customers. While manual slicing may have been the norm in the past, using a meat slicer has become an essential tool in the butchering industry. Not only can it help increase efficiency, but it can also ensure consistency and safety in the workplace.

Efficiency is critical in any business, and using a meat slicer can help butchers save significant amounts of time compared to manual slicing. With a meat slicer, you can cut through large quantities of meat in a matter of minutes, making it especially beneficial for busy butcher shops that need to fulfill customer orders quickly. Imagine being able to slice enough meat for ten orders in the time it would take you to do one order by hand. That’s the kind of efficiency you can expect from a meat slicer.

Precision is another significant benefit of using a meat slicer. Achieving consistency in your cuts is crucial when trying to deliver the perfect cut of meat for specific recipes or customer preferences. With manual slicing, it can be challenging to achieve the same uniformity every time. But with a meat slicer, you can adjust the thickness settings and get the perfect cut every time. This consistency is not only impressive but also helps ensure customer satisfaction and repeat business.

Safety is also an important factor when it comes to using a meat slicer for butchers. A sharp knife poses an increased risk of injury in the workplace. Meat slicers have built-in safety features that prevent accidental injury, such as protective guards and automatic shut-off switches. Using a meat slicer also helps reduce fatigue and strain on your hands and wrists, which can lead to muscle soreness and joint pain over time.

Moreover, investing in a high-quality meat slicer can prove to be cost-effective in the long run. By reducing waste and increasing efficiency, you can save money on labor and product costs. Additionally, using a meat slicer allows you to portion out meats accurately, which can help you control inventory and reduce overstocking.

Safety Measures When Using a Meat Slicer

There’s no doubt that using a meat slicer can make your job easier and more efficient, but it also poses serious risks if proper safety measures aren’t taken. As an expert on the topic, I cannot stress enough the importance of following these measures to prevent accidents and injuries.

First and foremost, proper training is essential. Butchers are trained to handle meat slicers safely, but for home users, it’s crucial to read the user manual carefully and watch instructional videos to have a better understanding of how to use the machine safely. Trust me; it’s better to take a few extra minutes to learn how to use it correctly than to risk injury or worse.

When operating a meat slicer, protective gear is a must. Cut-resistant gloves, aprons, and eyewear can help prevent injuries in case of any accidents. It may seem like overkill, but it’s better to be safe than sorry. After all, you wouldn’t go into battle without armor, would you?

Keeping the area clean is also critical. Any spills or food particles should be wiped away immediately to prevent slipping hazards. The area around the meat slicer should be kept clean and free from any obstacles.

Using a sharp blade is another vital safety measure – a dull blade can cause accidents and injuries as it requires more pressure to cut through food items. Always make sure to use a sharp blade that can easily slice through the meat.

It’s also crucial to always be aware of the blade’s position when handling a meat slicer. Ensure that your fingers are nowhere near the blade while operating the machine.

Finally, before cleaning or changing parts, always remember to turn off the power and unplug the machine from the electrical outlet. This step may seem like a no-brainer, but it’s easy to forget in the heat of the moment.

Skills Needed to Operate a Meat Slicer

Whether you’re a professional meat slicer in a butcher shop or a home cook who loves to slice their own meat, there are essential skills you need to have to ensure that the job is done properly, safely, and efficiently.

Firstly, it’s crucial to have knowledge of the different types of meat slicers available in the market. From manual, automatic, to semi-automatic slicers, understanding the features and benefits of each type can help you choose the right one for your needs.

Once you’ve selected your slicer, it’s time to learn about the anatomy of the meat and how it should be sliced. Different cuts of meat require different slicing techniques, so it’s important to have basic knowledge of how to slice them correctly. For example, slicing a beef roast requires a different technique than slicing deli meats like ham or turkey.

Knife handling is another crucial skill needed when operating a meat slicer. The blade on a meat slicer is sharp and can be dangerous if not handled properly. Knowing how to handle a knife safely and effectively is crucial when using a meat slicer. Wearing cut-resistant gloves and eyewear while using the slicer can keep your hands and eyes safe from any flying debris.

In addition to knife handling, understanding the safety features on the meat slicer itself is also important. Knowing how to properly set up and use safety guards and other safety features can prevent accidents and injuries. Keeping the area clean and being aware of the blade’s position is also crucial for safety.

Finally, good hand-eye coordination and attention to detail are essential when operating a meat slicer. Slicing meat requires precision and accuracy to ensure that the slices are consistent in thickness and size.

Cost Considerations for Purchasing a Meat Slicer

While cheaper options may seem tempting, a well-made meat slicer can save time and increase efficiency in the long run.

So, what are the key cost considerations to keep in mind when purchasing a meat slicer? Let’s explore:

- Blade Size: The size of the blade is a significant factor to consider. While larger blades come with a higher price tag, they can slice larger cuts of meat quickly and efficiently. However, if you only plan to slice smaller cuts of meat, a smaller blade may be more cost-effective.

- Blade Material: The material of the blade is another important consideration. Blades made from higher quality materials such as stainless steel will cost more, but they will last longer. In contrast, cheaper materials may wear down quicker and require frequent replacement.

- Power: The power of the meat slicer is also a cost consideration. A higher power means faster slicing, but it also comes with a higher price tag. It’s critical to balance the need for speed with your budget.

- Maintenance Costs: Finally, don’t forget to consider maintenance costs when purchasing a meat slicer. Blades will need to be sharpened or replaced over time, and regular cleaning and maintenance will ensure the longevity of the machine.

When purchasing a commercial meat slicer, prioritizing quality and durability over cost is crucial. Investing in a well-made meat slicer can save you time and increase efficiency in a butcher shop or restaurant kitchen.

Maintenance and Care for Your Meat Slicer

Neglecting to maintain and care for your equipment can lead to costly repairs and even contamination of your food. To ensure the longevity and efficiency of your meat slicer, it’s important to follow these key maintenance and care tips.

First and foremost, always refer to the manufacturer’s instructions for cleaning and maintenance. These instructions are specific to your model and will ensure that you are taking the appropriate steps to keep it clean and functioning properly. After each use, clean the slicer with warm, soapy water and dry it thoroughly with a clean cloth. This will prevent any residue buildup that can affect the quality of your slices.

Regularly inspecting the blade for any damage or dullness is also essential. A damaged or dull blade not only affects the quality of your slices but also poses a safety hazard. If you notice any damage or dullness, replace the blade immediately to ensure your slices are uniform and safe.

Lubrication is another important aspect of maintenance. Regularly lubricating the slicer’s moving parts ensures smooth operation. Consult the manufacturer’s instructions for specific lubrication requirements and follow them accordingly.

Proper storage is also crucial when it comes to maintaining your meat slicer. Cover it with a clean cloth or plastic wrap to protect it from dust and debris when not in use. Store it in a dry location with low humidity to prevent rusting.

By following these maintenance and care tips, you can extend the longevity of your meat slicer and consistently produce quality slices for years to come. As a butcher or restaurant owner, investing time in maintaining your equipment is essential for the success of your business and the satisfaction of your customers.

Common Mistakes Made While Using a Meat Slicer

Then you know how important it is to handle this powerful tool with the utmost care and caution. While meat slicers can make your job more efficient, they can also be dangerous if not used properly. In this article, we’ll discuss the most common mistakes made while using a meat slicer and how to avoid them.

Firstly, failing to clean your meat slicer thoroughly after each use is a big mistake. A dirty meat slicer can cause cross-contamination, leading to foodborne illnesses. Make sure to follow the manufacturer’s instructions for cleaning and maintenance to keep your equipment sparkling clean and safe for use.

Another mistake is not adjusting the blade thickness correctly. To get the best results, you need to set the blade thickness according to the type of meat you are slicing. A blade that’s too thin will shred the meat, while a blade that’s too thick will be tough to chew. Take your time and adjust the blade thickness accordingly.

Using a meat slicer without its safety features is another common mistake that can lead to injuries. The blade guard, food pusher, and non-slip feet are there for a reason – to protect you from accidental cuts or injuries. Always use these features properly when operating the machine.

A dull blade is also a mistake that can affect the quality of sliced meat and may lead to accidents. A sharp blade is essential for safe and efficient slicing, so make sure you check it regularly for damage or dullness.

Lastly, overloading the machine with too much meat at once can cause damage or even accidents. Instead, slice meat in small batches and allow the machine to rest between each batch.

Alternatives to Using a Meat Slicer

There are several alternatives that can help you achieve similar results.

Firstly, the old-fashioned method of using a sharp knife and steady hand remains a reliable option. While it may take longer than using a slicer, this method can still get the job done. Simply ensure that the knife is sharp and slice the meat as thinly as possible, applying consistent pressure with a back-and-forth motion.

Another alternative is to have the meat pre-sliced at the grocery store or butcher shop. This service may cost a bit more, but it can save you time and effort in the long run – especially for larger cuts of meat.

For those with a mandoline slicer, you can use this tool to slice meat thinly and evenly. Although typically used for vegetables, a mandoline slicer can also work for meat if the blade is sharp enough. Just remember to use caution and wear protective gloves to avoid potential injuries.

Lastly, some grilling enthusiasts swear by freezing the meat slightly before slicing it. This technique can make it easier to achieve thin slices with a sharp knife as the firmer texture reduces tearing and crumbling.

Conclusion

In conclusion, the meat slicer is an indispensable tool that has revolutionized the way butchers and other professionals slice meats. With lightning-fast speed and precision cuts, these machines have been used for centuries and continue to be a vital part of any modern butcher shop.

Choosing the right type of meat slicer is crucial for achieving optimal results. By understanding the differences between various models, you can make an informed purchasing decision that meets your specific needs.

Using a meat slicer offers numerous benefits for butchers, including increased efficiency, consistency in cuts, safety features, cost-effectiveness, and reduced waste. However, it’s essential to follow proper safety measures when using this powerful machine to prevent accidents and injuries.

Maintaining and caring for your equipment is also crucial to ensure its longevity and efficiency. Regular cleaning, blade inspection, lubrication, and proper storage can help extend the life of your meat slicer.

If you prefer not to use a meat slicer or don’t have access to one, there are alternatives available such as using a sharp knife or having the meat pre-sliced at a grocery store or butcher shop. Regardless of which method you choose, ensuring that your slices are consistent will result in better quality meals for yourself or customers.

In summary, whether you’re a professional butcher or just someone who enjoys cooking at home, understanding the importance of using a meat slicer can take your culinary skills to the next level.